Finally, a weekend with no rain forecast. Not that it wasn't the case last week, but these "meteorologists" seem to make guesses rather than actual predictions based on fact. Maybe I'm just bitter since it put a stop to my relaxation activities. Mainly, working on my RV!

So now that I can comfortably(?) lay under the RV and not get soaked, lets finish up the transmission oil cooler supplemental fan install. You know, that's an awful lot of words to just say "fan." We left off with all the parts assembled and ready to install.

|

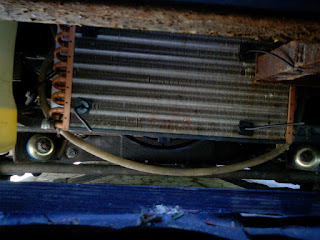

| My Transmission Oil Cooler in The Front Engine Bay |

First I attached the fan itself to the back of the transmission oil cooler. I thought about making it a "pusher" fan rather than a "puller fan" by mounting it on the front, but I believe I will get better airflow by sucking air up from below the front of the engine compartment rather than air from behind the engine and transmission. Once everything is in place, I'll put a temperature probe in there and see what's what.

|

| Opposite side from the Fan With Sticky Pad and Lock in Place |

|

| Hold Downs |

The fan get's mounted using long plastic hold downs with a circular stopper on one side and a spring and cap on the other. It is inserted through the tabs on the fan and through the cooler itself.

|

| Almost Finished Install - Viewed From Front |

You then slide on the supplied padded squares, with the sticky side toward the radiator, over the rod. These stick to the radiator and offer some padding and vibration resistance. Once done, make sure the fan turns freely and doesn't hit the cooler. If it does use a spacer or washer to add some gap. Too much gap is no good, as air will escape around the fan instead of cooling your transmission oil. Then comes the circular lock. BE CAREFUL! This will only go on once. It cannot be removed without destroying the rod or the plastic lock, so make sure everything is where you want it before you push them on. Once tight, snip the extra rod leaving a bit protruding.(1/4-1/2"-ish)

|

| Tight Install Behind Transmission Cooler |

I had very little clearance behind the transmission oil cooler, and the top of the fan hits the surround of the engine radiator's supplemental fan, but just a very little bit. It also hangs down a smidgen since the fan is actually 10" across even though the specs show it to be 9" wide. If I were to do this again (NOT!) I would buy an 8" fan so the total size would likely be 9". Ah well, at least when you buy a fan you'll get the right one!

|

| Accessory Switch is Second From Right, Bottom Row |

Next was the electrical hookup. This was, by far, one of the easiest I've ever done. The negative lead (BLACK) runs over to the Negative terminal of the battery or, even easier, to a convenient screw already in the chassis. (The Chassis/Frame IS a ground.) The other (POSITIVE) wire will go to one side of a switch near your driving position. Sometimes this is REALLY simple, but often can be tough since the wire MUST go through from the outside to the inside. Then the wire gets hooked up to a fused power source. This should be from your Engine's wiring, NOT the House system. There is usually someplace you can tap into within the existing fuse block. I used the ACCESSORY switch that was already in the dash, fused and unused. You can easily add a switch to your dash (or other convenient location.) If you cannot find power inside, you could run another wire back out, and down to the battery's positive terminal making sure you have a correctly sized fuse installed on the wire. If you go this route save time by running two wires at the beginning!

|

| Supplied Electrical Install Kit |

This is the time to decide if you'd like to install a thermostatic switch. It will turn the fan on at a predetermined temperature and back off when it is reached again. I have one, but didn't install it. I want to do some testing before I let the system work on it's own.

Once it's all hooked up, make sure that the fan turns the right way! If it's behind the cooler it should draw air THROUGH it from front to back. If it's in front it should push air through the cooler. If it's wrong, you likely have the wires reversed. On many fans this is the way to reverse the direction anyway so it's not too big a deal if you get it wrong. Just switch the wires at the fan and you're good to go.

WARNING! Some fan manufacturers want you to actually remove the fan blades and turn them over to switch the direction of the airflow. Switching the wires MAY damage this type of fan!

|

| Finished Install |

You should use heat shrink tubing or some other method to waterproof the connections that will be outside and usually underneath the RV. They will be subjected to some nasty elements like road salt, water...etc. It's a good idea to protect them. Yes, I know...put the heat shrink tubing on BEFORE you put all the wires together. See even I can learn after several mistakes!

I believe I will see some significant reduction in temperatures. Stay tuned, after the season I'll tally the results and write it all up.

See Part - 1

http://www.thewanderman.com/2012/06/keeping-it-cool-installing-transmission.html

Be Seeing You...Down The Road,

Rich "

The Wanderman"

www.thewanderman.com